Flex and Fix Systems

ProVac® Vacuum-systems

tailor-made

to suit Your needs

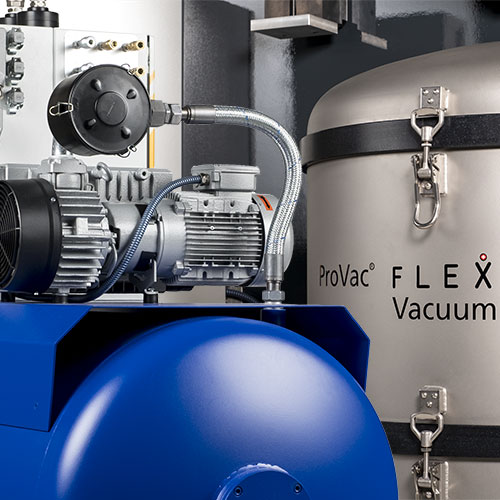

The ProVac® FIX or FLEX Vacuumsystems offer you a variety of options with virtually no limits. Using the ProVac® F L E X VacuumSystem you dispose of one single system to cast parts of multiple sizes and weights. Just insert additional elements to your existing vacuum-tank, from 200 up to 1000 Liter. Saving precious ressources is also good for the climate and your finances by the way.

ProVac®Vacuum-systems are as flexible as YOU and tailor-made to suit YOUR needs. They offer maximum flexibility, definitely the right solution for YOU, for years to corne. Simply clever!

ProVac®Vacuum-systems are as flexible as YOU and tailor-made to suit YOUR needs. ProVac®Vacuum-systems offer maximum flexibility, definitely the right solution for YOU, for years to corne. Simply clever!

- X Options in one single system

- Complete and extremly flexible

- Easy to place, wherever you want

- For tailor-made applications

- Industry 4.0

- Absolutely new and unique : Individual elements easy to add to the existing basic tank-size, extensible from 200 to 1000 litres

- Every single component (Control Unit, Pump, Tank) may be placed individually where you wish, with pumpsizes with 40 m3/h, 63 m3/h or even higher capacity

- For all valve-types such as metal-closed ProVac®Standard and for ProVac®Ultra EASY valves piloted by the diecasting machine

- For DCM from 600 to 44'000 kN

- High-value equipment with fully programmable logic control and numerous options and monitoring-functions to assure high-quality casts

The ProVac® FIX or FLEX Vacuumsystems offer you a variety of options with virtually no limits. Using the ProVac® F L E X VacuumSystem you dispose of one single system to cast parts of multiple sizes and weights. Just insert additional elements to your existing vacuum-tank, from 200 up to 1000 Liter. Saving precious ressources is also good for the climate and your finances by the way.

PROVAC® PLC & LC Full Option

Outside as you know it. Inside as you want it! This smart and “bright” system is as powerful as ever and now combines huge suction-capacity, with userfriendly and intuitive operating and monitoring capability.

- With measured volume of air!

- Remarkably compact in size it is designed for die casting machines of 6’000 – 44’000 kN and for really BIG casts

- Economic operation-mode of the vacuum-pump, running only when needed

- Various parameter-setting options

- Vacuum less than 20 mbar uk

- Graphic display of vacuum-curves and production-history, with Ethernet remote-control

- Storage of non-volatile “recipees” to monitor the quality of the casts

- 700-litres tank with 1 or 2 pumps 63 m3/h

- Optional: 1’000-litres tank with 1 or 2 pumps 63 m3/h

Ideal system for high expectations.

- AlIround-system with sheer power. For casts up to 30 kg Al shotweight

- For all valve-types and particularly suitable for ProVac®Ultra EASY valves piloted by the diecasting machine

- Easy to operate with intuitive touchscreen. Programmable logic control which may also be operated via Ethernet from a PC on the DCM or from the office

- For DCM from 6’000 – 38’000 kN

- 500-litres tank with pump 40 m3/h

Made to serve (almost) all needs!

- Robust and versatile

- Powerful system for various applications ito diecast parts up to 20 kg Al.

- For all valve-types and particularly suitable for ProVac®Ultra EASY valves piloted by the diecasting machine

- High-value equipment with programmable logic control and numerous options and monitoring-functions to assure high-quality casts

- For DCM from 6’000 – 32’000 kN

- 350-litres tank with pump 40 m3/h

Value for Money!

- Robust and versatile

- Although it is compact in size there is a lot of potential to evacuate air and gases from dies to cast quality-parts up to 20 kg Al shotweight

- High value for money combined with various options to program the unit and monitor the quality of casts

- For DCM from 600 – 25’000 kN and more than just simple parts

- 250-litres tank with pump 40 m3/h

Small and smart, the best to start!

- For vacuum-valves activated by liquid metal, chillvents and -inserts

- Value for money combined with various options to program the unit and monitor the quality of casts

- For DCM from 600 – 20’000 kN and simple parts

- 100-litres tank with pump 40 m3/h